UK's Best Meters

Sound and VibrationSvantek Academy UK

Acoustic MeasurementsAbout

Svantek UK

We are Sound and Vibration ExpertsSvantek UK is a subsidiary of a world-renowned manufacturer of noise and vibration monitoring instruments. Jointly established in 2011 with AcSoft, it offers a range of top-quality monitors known for innovation and technical excellence. Svantek prioritizes customer satisfaction and continuously strives to improve its products to meet the demands of the market. With over three decades of experience, Svantek has been at the forefront of innovation in sound and vibration monitoring technologies. Their product range includes noise and vibration measurement systems, air quality monitoring equipment, acoustic imaging, and specialized software. Svantek UK brings these advanced technologies to the UK, catering to diverse industries such as construction, automotive, aerospace, and defense. Among their notable offerings are the SV 803 Vibration Monitoring Station and the SV 307A Noise Monitoring Station, which exemplify their commitment to quality and technical excellence.

|

|

Lastest

NewsPC Software

Download

|

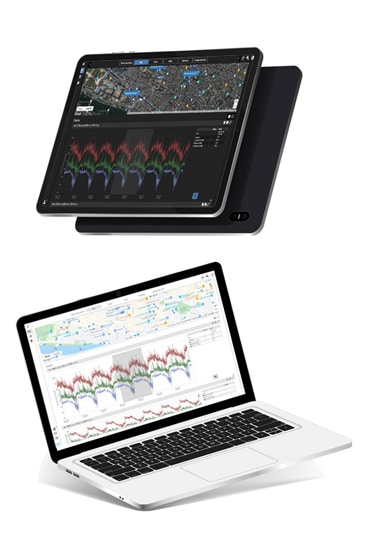

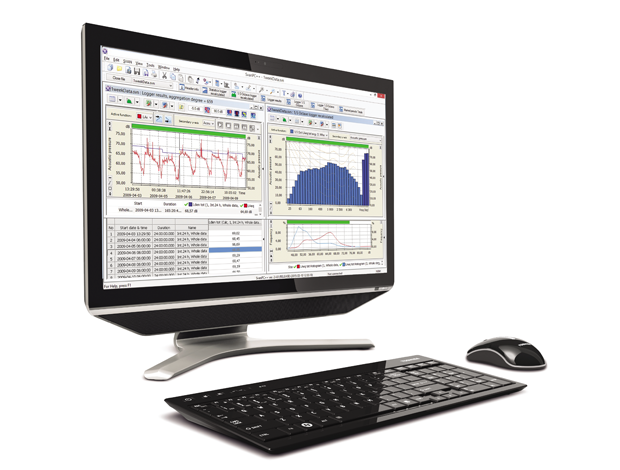

Meet Supervisor and SvanPC++ Svantek’s PC software plays a crucial role in measurement systems. SvanPC++ offers advanced data post-processing for raw wave and building acoustics data. The Supervisor software focuses on analysis and reporting of occupational noise and vibration measurements. Svantek provides free software updates to registered users. Sign up for the newsletter and register your products to stay updated.

|